| SPEED TABLE IN REVOLUTIONS / MINUTE | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| To obtain maximum performance of diamond useful, it is essential to use the proper peripheral speed for each type of material. This table shows the optimal speed (r.p.m.) which must work the diamond tool according to its diameter. |

|||||||||||||

|

PERIPHERAL SPEED

|

CUTTING BLADE diameter in mm | ||||||||||||

| 150 | 180 | 230 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 700 | 750 | 800 | |

| 15 | 1.950 | 1.600 | 1.250 | 1.150 | 960 | 820 | 720 | 640 | 575 | 480 | 410 | 385 | 360 |

| 20 | 2.550 | 2.150 | 1.700 | 1.550 | 1.300 | 1.100 | 1.000 | 850 | 770 | 640 | 550 | 510 | 480 |

| 25 | 3.200 | 2.700 | 2.100 | 1.950 | 1.600 | 1.400 | 1.200 | 1.100 | 960 | 800 | 685 | 640 | 600 |

| 28 | 3.600 | 3.000 | 2.350 | 2.150 | 1.800 | 1.550 | 1.350 | 1.200 | 1.100 | 895 | 765 | 715 | 670 |

| 32 | 4.100 | 3.400 | 2.700 | 2.450 | 2.050 | 1.750 | 1.550 | 1.400 | 1.250 | 1.050 | 875 | 815 | 765 |

| 35 | 4.500 | 3.750 | 2.950 | 2.700 | 2.250 | 1.950 | 1.700 | 1.500 | 1.350 | 1.150 | 1.000 | 895 | 840 |

| 40 | 5.100 | 4.250 | 3.350 | 3.100 | 2.550 | 2.200 | 1.950 | 1.700 | 1.550 | 1.300 | 1.100 | 1.050 | 955 |

| 45 | 5.750 | 4.800 | 3.750 | 3.450 | 2.900 | 2.500 | 2.150 | 1.950 | 1.750 | 1.450 | 1.250 | 1.150 | 1.100 |

| 50 | 6.400 | 5.350 | 4.200 | 3.850 | 3.200 | 2.750 | 2.400 | 2.150 | 1.950 | 1.600 | 1.400 | 1.300 | 1.200 |

| 63 | 8.050 | 6.700 | 5.250 |

4.850

|

4.050

|

3.450

|

3.050

|

2.700

|

2.450

|

2.050

|

1.750

|

|

|

| 80 | 10.200 | 8.500 | 6.650 | 6.150 | 5.100 | 4.400 | 3.850 | 3.400 | 3.100 | ||||

| 100 | 12.750 | 10.650 | 8.350 |

7.650

|

6.400

|

5.500

|

4.800

|

|

|

|

|

|

|

| RECOMMENDED SPEED FOR SOME MATERIALS | |||||||||

|---|---|---|---|---|---|---|---|---|---|

|

HARDNESS

|

CONCRETE | GRANITE | MARBLE | CERAMIC | |||||

|

Type

|

Speed m/s |

% Quartz | Classe | Speed m/s | Type | Speed m/s | Type | Speed m/s | |

| Soft | Fresh | 40 - 50 | 0 - 15 | 1 - 2 | 40 - 50 | White Crystalline |

50 - 60 | Double firing | 55 - 80 |

|

Middle

|

Old | 30 - 40 | 15 - 24 | 2 - 3 | 30 - 40 | Trani Botticino |

40 - 50 | Single firing | 45 - 55 |

|

Hard

|

Reinforced | 25 - 35 | 24 - 34 | 4 - 5 | 25 - 35 | Colored Arabescato |

30 - 40 | Porcelain | 40 - 50 |

| RECOMMENDATIONS FOR USE | |||

|---|---|---|---|

|

|

|

|

|

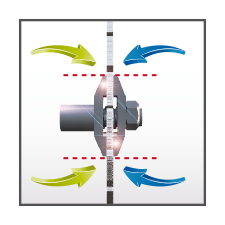

Adjust the axis of the machine

over which it is mounted. |

Always mount the disk

in the direction of rotation which is marked over the disc. |

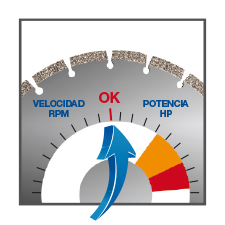

Verify that the power

and speed of the machine are appropriate. |

Check that the adjustment

plates are clean and the right measures. |

|

|

|

|

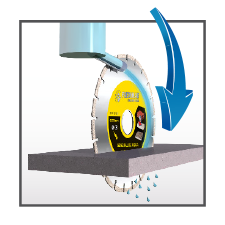

| Do not hit and press excessively. Light pressure is sufficient without penetration force disk. |

In wet cutting blades, verify that has sufficient water flow well directed to the cutting area. |

By starting and stopping the machine, take the disc out of the cutting area. |

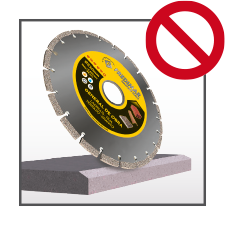

Do not use for side grinding. |